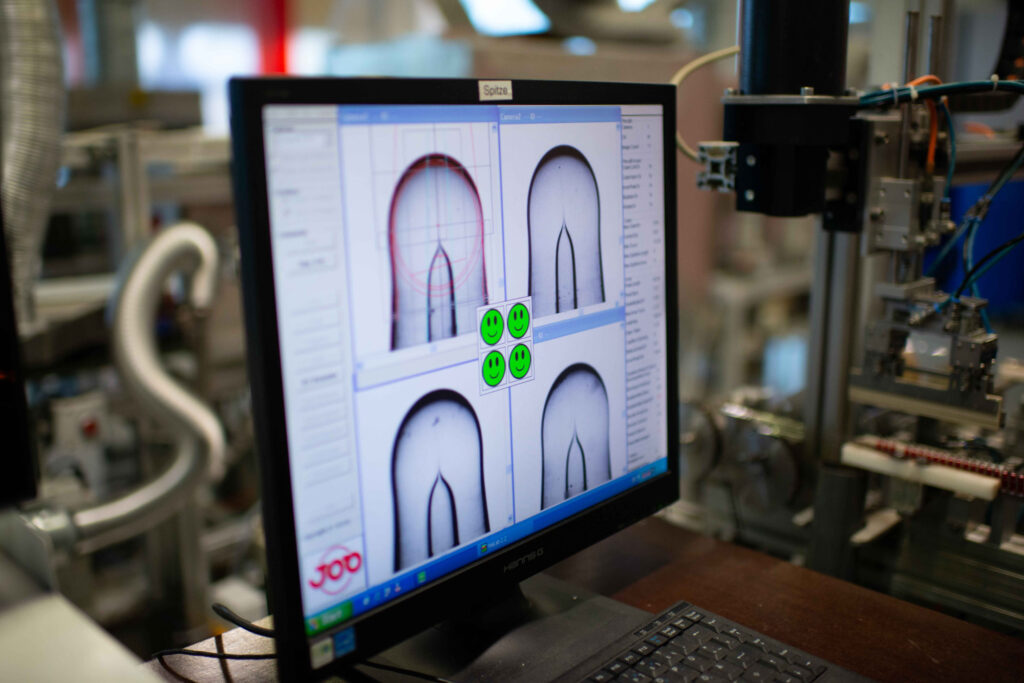

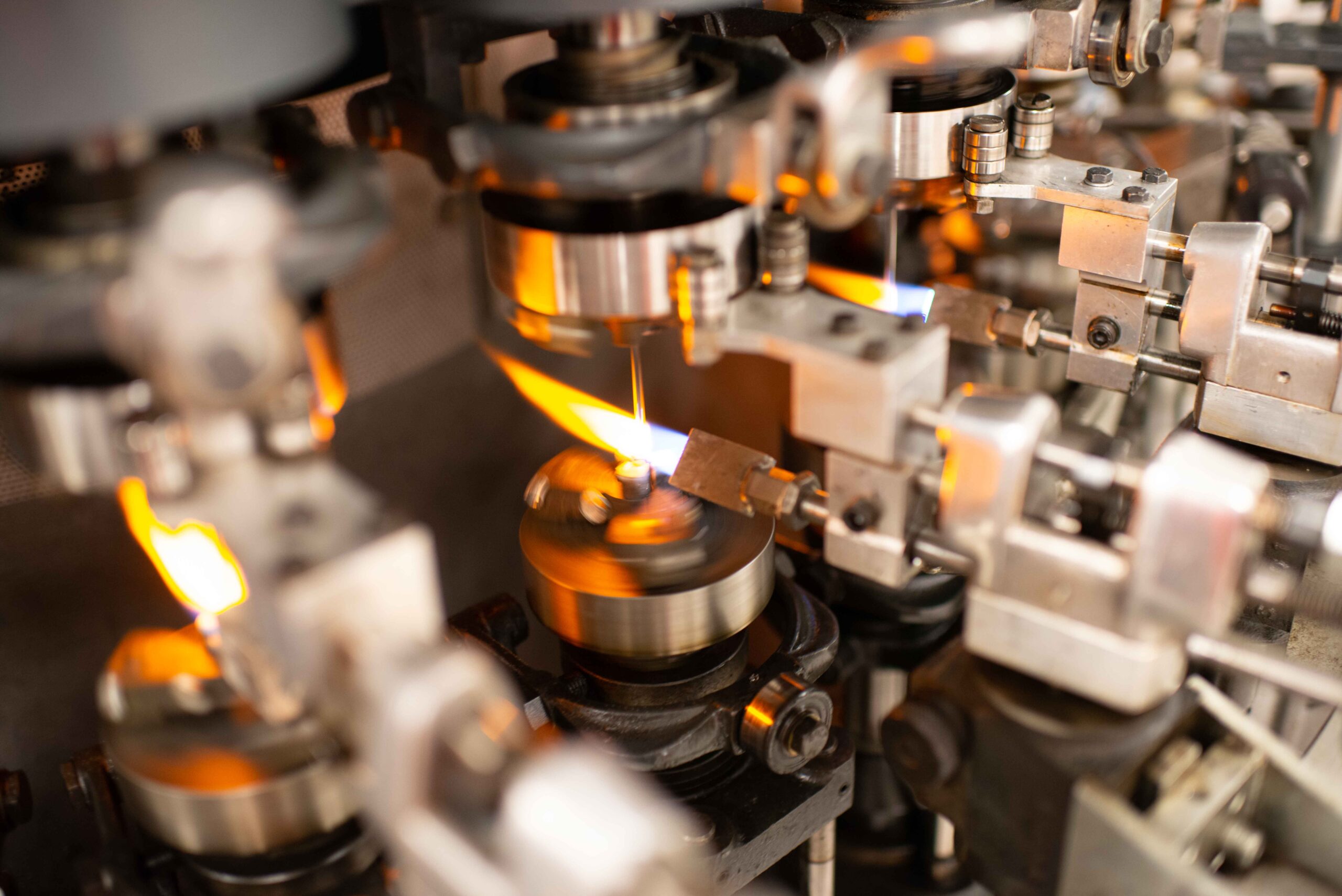

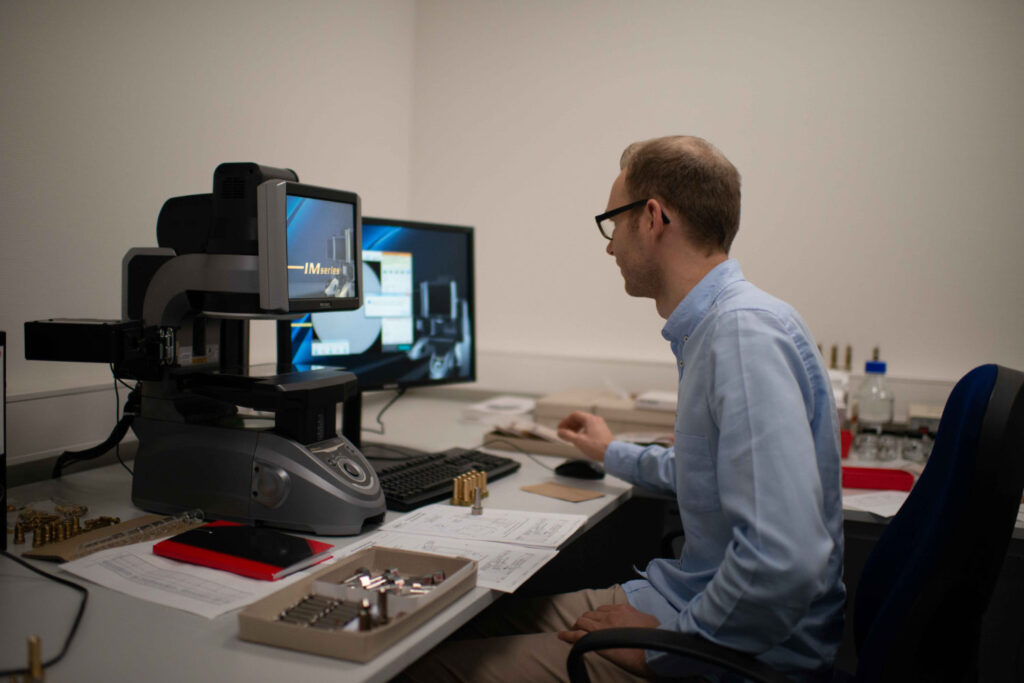

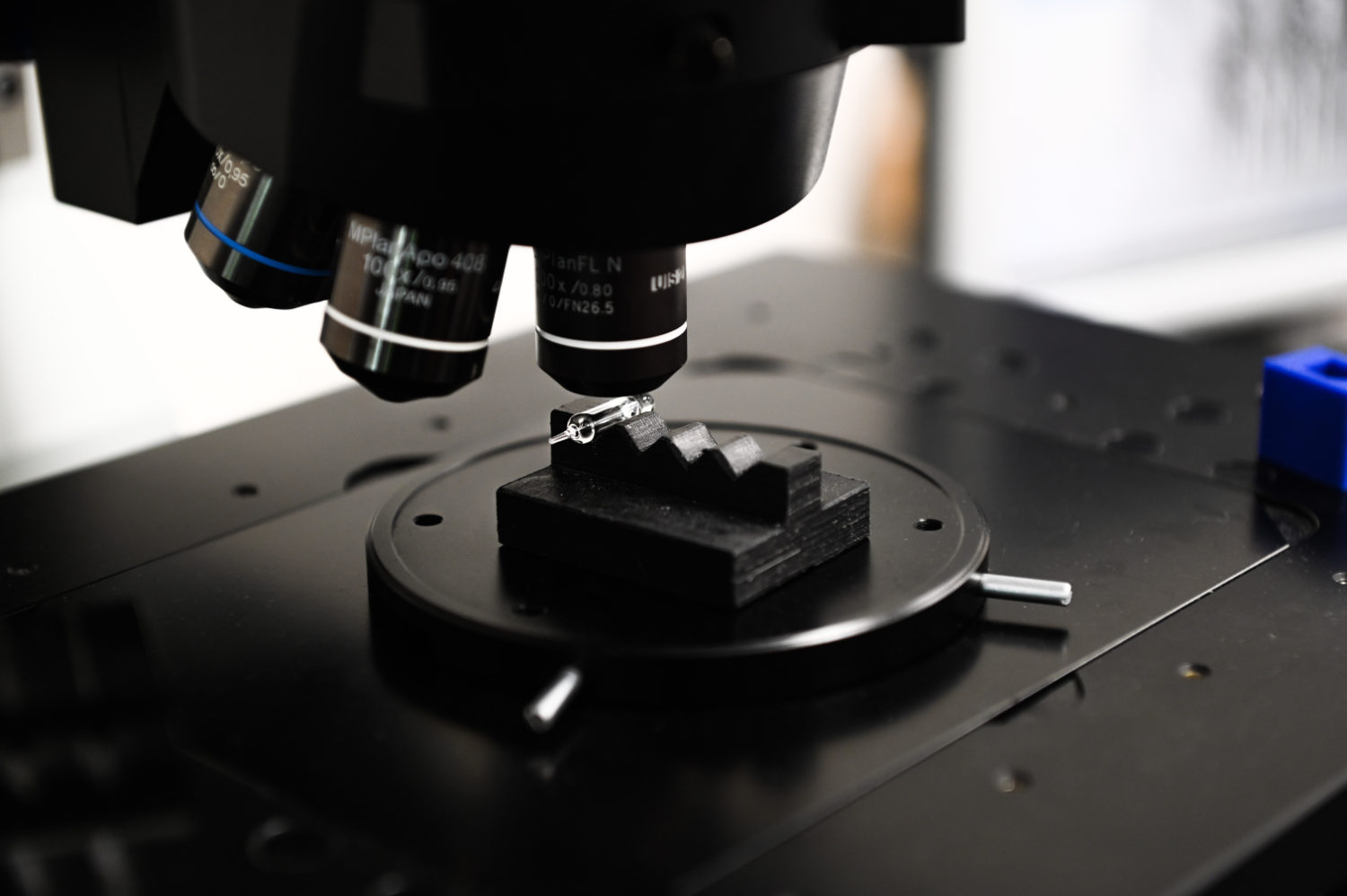

Quality management, standards, certifications. There are several reasons to think about this. For JOB, one of the most important things is to make the company strong for the future. The processes that are driven by our commitment to a holistic management system also contribute to this.

Customers and end users are placing increasing importance on environmental issues. This increases the trend towards certifications, and they are actively in demand. The ISO standard 14001 refers to all management issues related to environmental factors and their effects on us. This standard includes all activities to improve environmental impacts systematically and sustainably.