“The JOB company has been committed to quality for over 50 years. Our numerous audits and certifications in recent years can confirm this.”

Automatic miniature fire extinguishing unit

The AMFE automatically detects fires in control cabinets and electrical devices. The system prevents the spread of fire and further property damage. JOB’s AMFE protects devices and systems in industry-, household- and consumer electronics. (E.g. control cabinets, household appliances, monitors.)

We integrate our AMFE and E-Bulb extinguishing systems directly into devices or control cabinets so that fires are extinguished directly at the point of origin. In this way we protect the devices and do not leave any consequential damage after activation. Current operations can therefore be continued quickly, and repair costs are reduced to a minimum.

Control cabinets

Media technology

Train

Mining

Museums/

Collections

Shipping

Wind-power

Vending machines

Device-integrated fire protection as an important building block for greater resilience

The modern world is characterized by increasing complexity and a wide variety of challenges. The protection of critical infrastructures – KRITIS for short – is therefore a top priority.

Fire protection and digitalisation in harmony

The AMFE is installed purely passively directly in a box or cabinet to be protected. It is installed in such a way that it reliably detects an increase in temperature in the closed area, triggered by a fire, and triggers the extinguishing process when the selected trigger temperature is exceeded. This allows the non-conductive, non-toxic, and residue-free extinguishing agent to flow out.

In the event of thermal activation, an external signal current running via the S-AMFE is interrupted because the glass ampoule bursts, and the activation is reported.

A connected relay or controller recognises this and opens the power contacts, for example.

As a result, the power to the device is switched off and reignition is prevented.

The R-AMFE can be triggered using an external activation current. The ampoule inside is specifically overheated and bursts when the activation temperature is reached. In addition to this electrical triggering, the R-AMFE can also trigger purely thermally.

Depending on the expected temperature inside the housing to be protected, the trigger temperature is chosen. JOB offers four different trigger temperatures as standard. If other triggering temperatures are of interest, please contact us. Individual release temperatures are possible with appropriate purchase quantities. When retrofitting, we recommend a temperature measurement in normal operation (or thermography measurement) and a safety margin of approx. 20 Kelvin to prevent possible early triggering in special temperature conditions (sunlight in summer).

Insurance against business interruption makes sense, but it is better if fire protection integrated into the device ensures that expensive business interruptions do not occur in the first place.

In the event of a fire, the insurance company pays an agreed amount of money; on the one hand, this usually does not cover the entire amount of the destroyed property, and, on the other hand, the replacement of the destroyed property takes time and money.

The sooner you extinguish the fire, the less damage is caused – integrated fire protection devices make sense

If the conditions for a fire are met, the ignition phase takes place. During the ignition phase the temperatures are relatively low. The subsequent smouldering fire phase causes heating up to a certain limited temperature. Depending on the fire, this phase can take a long time (e.g. smouldering fire). Once this limit is reached, all combustible substances in the room ignite; this is referred to as a flashover. The earlier a fire is discovered and fought; the less consequential damage can be expected. Device-integrated fire protection makes sense because electrical fires are fought directly at the source of the fire within the electrical device.

In contrast to other extinguishing systems, the AMFE system does not leave any consequential damage after extinguishing

In contrast to aerosol extinguishers, or foam or water-based extinguishing systems, AMFE extinguishing systems are characterised by the fact that they do not leave any consequential damage after extinguishing. After activating the AMFE, the extinguishing gas is distributed throughout the electrical device and extinguishes the fire. The extinguishing agent is residue-free. If there is an interruption to operations, it is significantly shorter than with extinguishing systems, which cause major collateral damage. The AMFE makes sense.

In contrast to other extinguishing systems, the AMFE system does not leave any consequential damage after extinguishing

Risk engineers at property insurers highly value the AMFE mini fire extinguishers because they protect against devastating fires and expensive business interruptions in the event of a fire. The advantages are particularly great when it comes to protecting sensitive areas, important machines, or control cabinets, as well as critical infrastructure. Insurance companies often pass on the added value of risk reduction to their customers in the form of reduced premiums or higher insured sums. Talk to your property insurance company.

In addition to the financial aspects, the use of AMFE is worthwhile to increase security for employees, customers, or other people who are protected by AMFE. When AMFE is installed in mass produced products, product safety is also increased.

In sensitive areas, such as shopping centres, trade fairs, airports or train stations, electrical devices often go from being the “causing fire” to being the “involved in the fire”. By installing and using device-integrated fire protection, electrical devices such as digital signage and LED advertising screens become safer. This means that printers, televisions, or advertising boards can often receive installation approval, even in escape route areas.

The annual maintenance costs for the AMFE system are low versus other extinguishing systems because maintenance does not have to be carried out by certified specialist personnel.

The costs of standard maintenance contracts can be saved!

AMFE – Simply. More. Safety.

As a manufacturer or operator, you can use AMFE to be an important step ahead of your competitors because:

Due to high fire risks, every major manufacturer has had to recall devices ranges in recent years. This can lead to a loss of image, which can easily be prevented. Sometimes there is even no need to recall the entire range. A simple service case occurs for individual defective devices.

Different fire protection concepts can be used when designing electronics. Our aim is to increase the safety of electrical devices. By using AMFE, the overall product costs can be reduced, for example by reducing or replacing flame-retardant materials. These materials are also often criticised for being harmful to the environment – quite the opposite of the extinguishing agent integrated in the AMFE.

“The JOB company has been committed to quality for over 50 years. Our numerous audits and certifications in recent years can confirm this.”

“Sprinkler systems protect lives and property. The JOB group with their Thermo Bulbs has been supporting global programs to increase fire protection through automatic extinguishing systems for decades.”

“FM as an industrial insurance company attaches great importance to fire protection through extinguishing systems recognized by us. With its high-quality products, the JOB Group also supports the IFSA (Int. Fire Sprinkler Alliance) in developing regulations worldwide to protect human lives and property.”

EWM GmbH, a leading welding technology supplier, maintains high quality standards backed by advanced testing and safety systems. To prevent operational failures, the company focused on protecting electrical components. In late 2023, intelligent mini fire extinguishers were installed in nine electrical systems in cooperation with Wichmann to suppress incipient fires directly at their source.

The Berlin-based start-up Rechargy uses an innovative business model that involves renting out power banks and setting up “Power Banks To Go” stations. The Rechargy stations are located in public areas and are therefore subject to strict fire safety and security requirements. Thanks to AMFE, the charging and power electronics areas are reliably protected.

Step 1

Temperature in the control cabinet

Step 2

Control cabinet size

Step 3

Maintenance

Step 4

Signalling and remote triggering

Applies to continuous control cabinets or larger volumes! Multiple AMFEN can be triggered simultaneously with our R-AMFE. If you have any further questions, please contact your specialist partner directly.

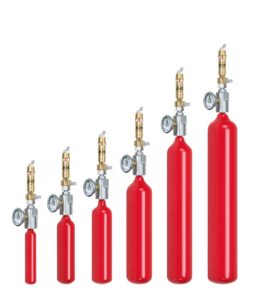

| Protected Volume [in litres]* | Size |

|---|---|

| 42 | 0 |

| 137 | 1 |

| 229 | 2 |

| 459 | 3 |

| 686 | 4 |

| 1.149 | 5 |

| FK-5-1-12 as fire extinguishing agent | |||||||

|---|---|---|---|---|---|---|---|

| Physical Dimensions Cylinder | Mounting Brackets | FK-5-1-12 Content | Protected volume (m3)* | ||||

| Size | Size Diameter x Length (mm) | Size Diameter x Length (inch) | Recommended brackets | FK-5-1-12 Volume (ml) | Class A fire VdS 2381 (5,8%) | Class A fire EN15004-2 (5,3%) | Class A fire NFPA 2001 (4,5%) |

| #0 | 22x128 | 7/8 x 5.04 | RGSS 22 | 24 | 0,046 | 0,050 | 0,060 |

| #1 | 35x154 | 1 3/8 x 6,06 | RGSS 35 | 72 | 0,137 | 0,151 | 0,179 |

| #2 | 40x186 | 1 9/16 x 7,32 | RGSS 40 | 120 | 0,229 | 0,251 | 0,299 |

| #3 | 51x251 | 2 x 9,88 | 2x RSGU 56 | 241 | 0,459 | 0,505 | 0,600 |

| #4 | 51x356 | 2 x 14,02 | 2x RSGU 56 | 360 | 0,686 | 0,754 | 0,896 |

| #5 | 60x380 | 2 3/8 x 14,96 | 2x RSGU 63 | 603 | 1,149 | 1,264 | 1,501 |