PROJEKTZUSAMMENFASSUNG

CASE STUDY

WKK KALTBRUNN AG

WKK KALTBRUNN AG RELIES ON AMFE FOR GREATER SAFETY IN PRODUCTION

For over 50 years, WKK Kaltbrunn AG has been successfully holding its own in the highly competitive market for stamping technology. The company processes around 2,500 tons of steel annually and

stands for precision, innovation, and quality “Made in Switzerland.” With around 45 employees, WKK has developed from a traditional toolmaker into an internationally active stamping company. Its core competencies range from design and toolmaking to the series production of stamped, bent, and formed parts. State-of-the-art processes such as stamping, deep drawing, bending, forming, joining, and assembly enable the highest quality and efficiency. The company attaches particular importance to customer proximity, innovative strength, and cost efficiency – values that have made WKK a strong partner in the supply industry for decades.

The challenge

Production using punching technology naturally involves risks: electrical installations, machines, and high material throughputs can quickly lead to smoldering fires or even larger fires in the event of an emergency. In fact, WKK has already experienced a smoldering fire caused by 24-volt cables. Fortunately, worse consequences were prevented, but management decided to invest even more heavily in preventive fire protection in the future in order to protect both employees and machines.

The solution: AMFE

In its search for a reliable and straightforward solution for preventive fire protection, WKK opted to use AMFE (Automatic-Miniature-Fire-Extinguisher).

The reasons for the decision

• Easy installation: The AMFE can be installed in just a few minutes – significantly faster than comparable

systems on the market.

• Easy maintenance: Thanks to its well-thought-out design, maintenance is particularly easy.

• Safe in case of emergency: Initial extinguishing measures are carried out automatically – without putting

employees at risk.

With the successful introduction of AMFE during ongoing operations, WKK has taken an important step toward safety and sustainability. Further projects with AMFE are planned for the future – as a contribution to the protection of employees, production facilities, and continuous delivery capability.

Kontakt

Das könnte Sie auch interessieren:

Small extinguishing system protects EWM technology centre

EWM GmbH, a leading welding technology supplier, maintains high quality standards backed by advanced testing and safety systems. To prevent operational failures, the company focused on protecting electrical components. In late 2023, intelligent mini fire extinguishers were installed in nine electrical systems in cooperation with Wichmann to suppress incipient fires directly at their source.

Hospitals rely on AMFE for protection

Integrated fire protection for Digital Center News-Club

Integrated fire protection protects European XFEL accelerators

Secured water supply for the citizens of the Weißenthurm community

Automatic miniature fire extinguishing unit in service column

Airport Berlin (BER)

Household appliance manufacturer Liebherr relies on mini fire extinguishers

Duisburg energy service provider relies on AMFE

AMFE protects control cabinets for air conditioning and cooling control systems

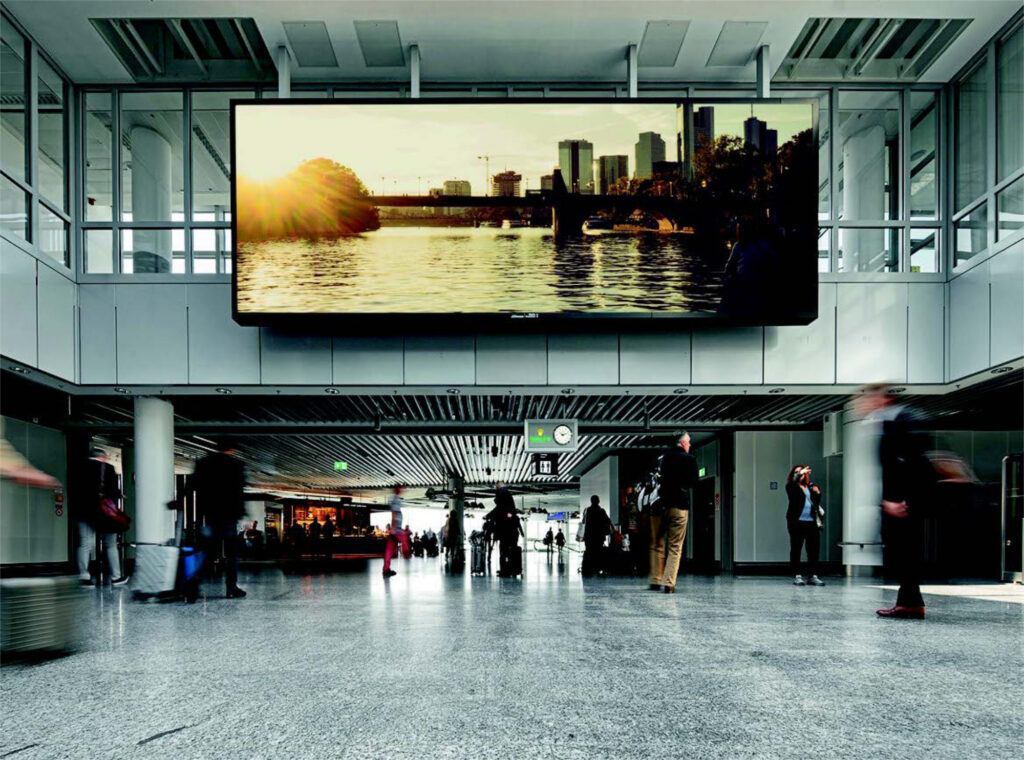

JOB supplies high-tech fire extinguishing ampoules for Samsung Media Displays at Frankfurt Airport

INTEGRATED FIRE PROTECTION FOR DIGITAL MEDIA TECHNOLOGY

Berlin-based start-up relies on AMFE for protection

The Berlin-based start-up Rechargy uses an innovative business model that involves renting out power banks and setting up “Power Banks To Go” stations. The Rechargy stations are located in public areas and are therefore subject to strict fire safety and security requirements. Thanks to AMFE, the charging and power electronics areas are reliably protected.